DO IT YOURSELF GRANITE FAQ's

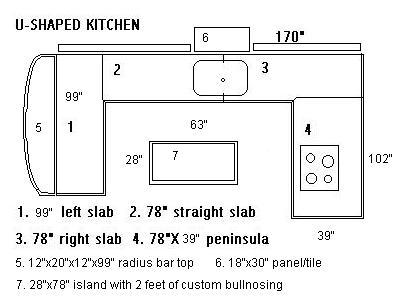

Example of how to place seams and slabs in your kitchen. Notice that a small seam is hidden in sink hole. Other seams occur near corners. Please email us for other sample plans like corner sinks, diagonal corners, large islands etc. You may fax us at 877-349-4726 (auto-sensing) with your kitchen plans if you are unsure what to order (put a dotted line where you want bullnosing and a double-line where you want backsplash). Also include your windowsill size in case you want it bullnosed as well (sometimes there is some left over).

-

Are the following instructions all that is needed to install countertops?No. With your purchase we give you special instructions and templates for doing inside corners and surface mount holes that are not found here and make the job a lot simpler. You also receive as much advice as you need for your particular installation. Some of the following instructions may NOT be suitable for your application.

-

How do I prepare my cabinets for Granite countertops? Although not

necessary, it is recommended that you apply ¾ inch plywood sub-counter

to the top of your cabinets to support the granite. This will add support

above appliances such as dishwashers and compactors, support holes for

sinks and cooktops and also help support small cantilevered ends and breakfast

bars. The slabs can be glued to this plywood surface using thinset, liquid

nails subfloor adhesive or a two part (bondo) type adhesive. The other

advantage to plywood is that you can level the slabs much more easily without

moving them once they are in place (see next question). In any event, if

you are using frameless (european type ) cabinets or framed cabinets that

have upper retractable cutting boards, you will need to raise the granite

¾ inch to clear the double bull-nose which hangs down ¾ inch.

Plywood is a cheap and easy way to do that.

-

One side of my counter has to be made up of two sections of countertop.

How is this done? Almost all kitchens will have seams in the granite.

Usually they are difficult to see from a distance. If you look for them,

you will find them. If the granite is seamed at the factory cuts, it is

as easy as laying the granite slabs next to each other, putting the seaming

material on the edges and then squeezing them together, wiping away most

of the excess material. Some of the excess material is left so that you

can sand it off level. It is important that the two slabs be at the same

level. This is accomplished by driving screws up from inside your base

cabinets, through the ¾ inch plywood sub-counter, to raise or lower

the slabs. The seaming material can be silicone, 60 minute epoxy or other

2-part polyester resins. Although silicone may be used, the industry usually

uses the epoxies or polyester resins. They can be tinted and polished to

hide more effectively. NOTE: We have a new procedure with our Seamstone(tm) Kit to make this MUCH easier (with large discounts to our granite customers).

-

How do I cut an inside corner? Typically a corner in granite is

done as a butt joint. In this system, since the granite comes with bullnosing,

24 inches of the bullnose is cut off of one side and the other side is

butted against this. Only the bullnosing itself (approximately 1.5 inches)

is cut at a 45 degree angle. It is best to use ....(we give you this information with your order).... should be as large as the slab. This way you will know (...) the slab or if the corner is not 90 degrees. If the ...(with your order)..., the slab will fit. A 45 degree cut all the way through the granite

slab is usually only done for a heavily veined granite so that the veins

line up--a totally aesthetic decision that costs 4 sqft of granite. A butt

joint is also much easier to cut with a circular saw and straighten with

a grinder (if necessary). We have a new tool, the Kwik-Korner(tm) jig to make the 45 degree cut easier and more accurately (with large discounts to our granite customers).

-

How do I cut out a hole for a self-rimming sink? Self rimming sinks

are sinks that lay on top of the granite and typically have a rim that

is one-half inch larger than the hole (cut-out) they fit into. Most newly

purchased sinks either come with a paper template or describe the cut-out

and give dimensions. In either case the template or dimensions must be

transferred to the granite where the sink is to be placed. Try to leave

at least 2.5 to 3 inches of granite on front and back Always double check

your planned cut-out against the actual sink with a tape measure. Many

manufacturers have more than one sink style on a template so make sure

you have the right one. Before you do any cutting, support the entire length

of the slab of countertop with 2x4ís so that its weight is evenly distributed.

Make sure none of the blocks are under your cut-out. Or, alternatively,

lay the granite on 3/4 inch styrofoam on a table. Cut the straight lines

of your cut-out with a circular saw with a diamond blade. If you are dry-cutting

make sure you use a segmented or good turbo-cut blade. Hold the front of

the saw down and sink the saw into the granite. Next, cut an X into the

middle of your cut-out and then cut another X like you are slicing a pizza.

Most kitchen sink templates have 4 inch radius corners. The corners are

cut using a 4 inch grinder with a diamond blade. Cut at an angle at least

half way through the granite. If you canít cut on the line then make the

hole smaller (you can always fix the hole later with the grinder). Next,

just drop out the triangles, knocking gently. A circular template, usually

found in bathrooms, would be cut out mostly with the grinder. The center

cuts could still be done with a circular saw. With your order you will receive an instruction template that can drop out the center of the sinkhole with no dangerous knocking and only cutting from above. Also you will get instructions on simple but effective reinforcement.

-

How do I cut out a hole for a cook-top? Follow the same instructions

as for a self rimming sink. You will normally find that the template for

a cook-top has 90 degree corners, making it easier. We do send you better instructions and "tricks of the trade" with your order.

-

How do I cut out a hole for an under-mount sink? You follow the

procedure for a self-rimming sink except that you will make the cut-out

one half inch smaller than what you want to end up with on the corners.

They will have to be straightened out with a 4 inch silicon-carbide grinding

stone so that they have a smooth uniform radius. The straight lines will

have to be cut more carefully and slowly, preferably wet-cut and using

a jig (2X4 clamped to the granite) to keep your saw straight. The edges

can be polished by hand using a polishing kit made up of velcro-lined pads

of 8 different grades of special diamond embedded "sand paper". The sink

is mounted underneath after applying silicone to the mounting rim and is

held up with wood or metal supports screwed into the upper front and back

of the base cabinet. Better instructions for doing this are supplied with the Rotary Polishing Kit for granite.

© 2000-2003 Do It Yourself Granite, All Rights Reserved © 2000-2003 Do It Yourself Granite, All Rights Reserved

|